Body: Mounting the Skirt

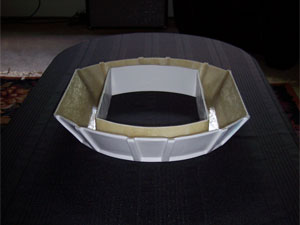

The skirt was one of my first part purchases for R2. I picked it up back in 2005 for $90. It's

made of fiberglass, which is rare these days as it seems most club members have gone to aluminum,

styrene, or molded plastic.

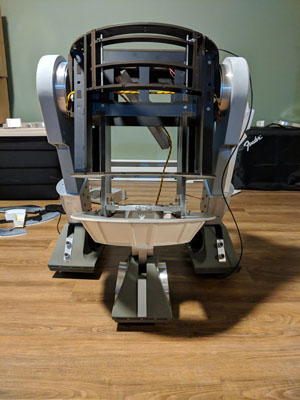

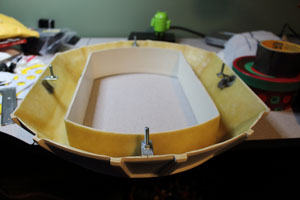

As you can see from the photos, there's not much to bite on for mounting purposes.

My recollection from back in the day was that most folks were epoxying L-brackets

to the insides of the skirt, slipping bolts through them and into holes drilled into

the breadpan of the frame. So that's the approach I took here.

I picked up some L-brackets from Lowes that would accommodate some 10-32 bolts

and bent them at an angle so that once they were attached to the skirt, the

tops of the L-brackets would be level.

I should point out that my L-brackets aren't flush to the top of the skirt. The bolts I used

are inserted from within the skirt and need to be secured with a nut to the L-bracket before attaching it to

the body. So I added a little breathing room on top for a nut to sit against the L-bracket.

I then marked off four locations around the outside perimeter of the skirt. And because

I didn't have any other epoxy with me at the time, I just used JB Weld. Time will tell

if I'll regret this. I then taped the L-bracket in place while the JB Weld cured.

Once the JB Weld cured, I inserted 10-32 2" bolts and secured them to the L-brackets with nuts.

I then flipped over my R2 and slowly and carefully positioned the skirt on the breadpan

in order to figure out where to mark my holes for drilling.

After I drilled the holes, I gave them a quick filing to remove burs and then slotted

the skirt's bolts. I secured the bolts to the breadpan using 10-32 wingnuts.

Hopefully, the JB Weld holds. I have no idea how well it works with fiberglass, if at all. If the

skirt falls off once R2 gets a little mileage, I'll update this page with a better solution.