(Note: This is a slightly modified excerpt of Chapter 1 from a book I’ve been working on entitled “Digital Audio for C++ Programmers.”)

The decibel is perhaps one of the most confusing and misunderstood topics in audio. It has a confusing formula that appears to change based on the context. It’s also used in a variety of applications beyond audio. In fact, much of the documentation you’ll find is actually related electronics and telecommunications. And to muddy things even more, by itself the plain ole decibel doesn’t even really convey much meaning. It merely relates one power value to another. So, if after reading this article, you still find decibels confusing, don’t fret. You’re in good company.

The decibel originated with telephony in the early 1900’s. It was used as a way to describe the power efficiency of phone and telegraph transmission systems. It was formally defined as 1/10th of something called a bel. Interestingly, the bel was rarely used. The decibel got all the glory. The decibel has since found its way into all sorts of other domains, such as optics, electronics, digital imaging, and, most importantly to me, audio.

There are two benefits to using the decibel. The first is that switching to a logarithmic scale converts an awkward range of values (e.g., 0.0002 Pascals – 20 Pascals) to something much easier to reason about (e.g., 0 dB SPL – 120 dB SPL) . The other benefit applies to audio – a logarithmic scale is much closer to how the human ear actually hears. With a linear scale, like Pascals, doubling the value doesn’t usually feel like a doubling of loudness. With decibels, we actually get a scale that’s much closer to how to perceive loudness.

The decibel, in the generic sense, is not strictly a physical unit. When we think of physical units, we typically think about things like Amperes (number of moving electrons over time), Pascals (pressure), meters (distance), Celsius (temperature), etc. These are absolute units that correspond to physical things. The decibel isn’t like that. It’s a relative unit. It provides a relation of two things, which are themselves physical units. And it does this on a logarithmic scale.

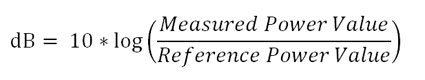

The general formula for the decibel is as follows.

The decibel, abbreviated dB, is the logarithmic ratio between two power values. One of these two values is a reference value. The other is a measured value.

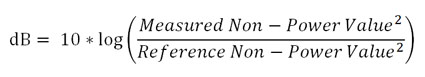

You may notice the phrase “power value” in that formula. In physics, this means the amount of energy transferred over time. The unit for power is usually the watt. However, there are plenty of units used that aren’t power values (such as Pascals in acoustic audio). So we have to convert those units into something related to power. This typically just means squaring the measured and reference values. The decibel formula ends up looking like so.

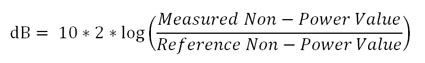

With logarithms, we can pull that exponent out and turn it into a multiplication.

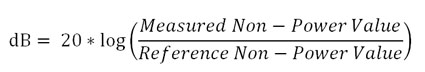

This can be simplified even further like so.

And this is the formula you’ll most likely encounter when applying the decibel to measured and reference units which aren’t power-based (like Pascals in acoustic audio). It’s just a derivation of the original formula with the measured and reference values tweaked.

Standard Reference Values

A lot of domains, such as electronics and audio, have standardized reference values for the various things being measured. When we talk about these standardized flavors of the decibel, we add suffixes to the dB abbreviation. Examples of this are dBV (voltage based), dBm (radio power), dBZ (radar power), etc. The one we’re most concerned with in the field of acoustic audio is dB SPL.

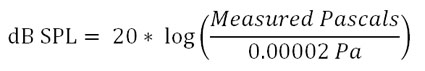

dB SPL

dB SPL is the most common flavor of decibel for indicating the loudness of acoustic audio. SPL stands for sound pressure level. The reference value used in calculating dB SPL is the threshold of human hearing – 0.000020 Pa. We plug this into the decibel formula along with a measured value, also in Pascals, to come up with a dB SPL value.

A measurement of 0 dB SPL is considered the threshold of human hearing. That is, it’s the quietest sound that the human ear is capable of hearing. On the upper end of the scale, somewhere between 130 dB SPL and 140 dB SPL, is what’s referred to as the threshold of pain. When the volume of sound approaches this level, it can result in physical discomfort and some amount of hearing loss is almost certain.

The following two tables shows some common sounds and their approximate sound pressure measurements. The first table shows measurements in Pascals. The second table shows them in dB SPL. Compare them and you’ll see that dB SPL is much less awkward to use.

| Sound Source | Distance from Ear | Pascals |

| Jet Engine | 1 meter | 632 |

| Threshold of Pain | At ear | 20 – 200 |

| Yelling Human Voice | 1 inch | 110 |

| Instantaneous Hearing Loss Can Occur | At ear | 20 |

| Jet Engine | 100 meters | 6.32 – 200 |

| Chainsaw | 1 meter | 6.32 |

| Traffic on a Busy Road | 10 meters | 0.2 – 0.63 |

| Hearing Loss from Prolonged Exposure | At ear | 0.36 |

| Typical Passenger Car | 10 meters | 0.02 – 0.2 |

| Television (typical volume) | 1 meter | 0.02 |

| Normal Conversation | 1 meter | 0.002 – 0.02 |

| Calm Room | Ambient | 0.0002 – 0.0006 |

| Leaf rustling | Ambient | 0.00006 |

| Threshold of Hearing | At ear | 0.00002 |

| Sound Source | Distance from Ear | dB SPL |

| Jet Engine | 1 meter | 150 |

| Threshold of Pain | At ear | 130-140 |

| Yelling Human Voice | 1 inch | 135 |

| Instantaneous Hearing Loss Can Occur | At ear | 120 |

| Jet Engine | 100 meters | 110-140 |

| Chainsaw | 1 meter | 110 |

| Traffic on a Busy Road | 10 meters | 80-90 |

| Hearing Loss from Prolonged Exposure | At ear | 85 |

| Typical Passenger Car | 10 meters | 60-80 |

| Television (typical volume) | 1 meter | 60 |

| Normal Conversation | 1 meter | 40-60 |

| Calm Room | Ambient | 20-30 |

| Leaf rustling | Ambient | 10 |

| Threshold of Hearing | At ear | 0 |

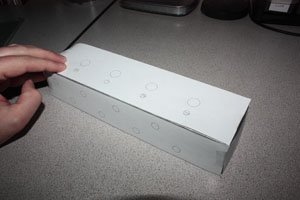

There are instruments available that measure sound pressure levels and report dB SPL. One such instrument is shown below. This happens to be my personal db SPL meter.

These devices are fun to take to concerts or demolition derbys if for no other reason than giving you the intellectual authority to complain about permanantly damaged hearing.

Conclusion

Hopefully, this article has helped demystify the decibel. Mathematically, they’re not something to be feared. It’s usually the logarithms that scare folks away. And if you’ve long since forgotten how logarithms work, go brush up on them and come back to this article a second time. It will make a lot more sense.

If you found this content useful, or if something could have been explained better, please leave me a comment below.

Until next time.